BUILT TO LAST

Our Innobella Textile Inks have scored 4.0 or higher on AATCC wash tests, proving that they are extremely durable and washable. Lasting you years to come.

Impressive Quality!

Nothing beats us

We utilize superior direct-to-garment & direct-to-film printing methods, allowing us rapid turn around times and wide color gamuts that screen printing simply can not touch. All with quick setup times and NO minimum order quantities.

environment friendly

Our newly formulated inks are water based, Okeo-Tex Eco-Passport certified, and CPSIA compliant. And our innovative replaceable ink pouches use less plastic reducing our ecological footprint.

the process

Step 1 - Pretreat & Cure

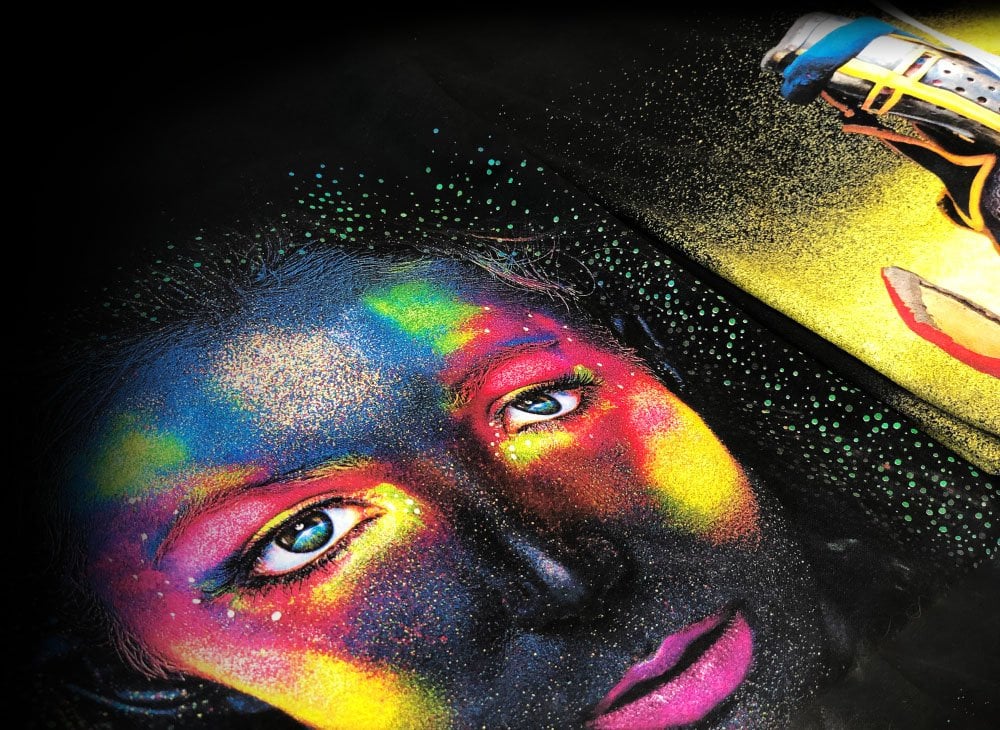

White ink is required as an underbase when printing colored images on dark garments, creating a blank white canvas so to speak. This is to ensure the colors pop on the dark clothing. When printing with white ink, we start by applying the proper amount of pretreat depending on the garment. Then simply cure the pretreat solution with either a heat press or dryer to ensure a flat printing surface. This also allows the white ink to adhere and solidify on the fabric, preventing dye migration and allowing the second layer of CMYK color inks to really stand out at 1200 x 1200 DPI.

Step 2 - Prepare the Artwork

Next, we work on design of the artwork in various graphics programs at our disposal. Since our printer uses two state-of-the art on-demand piezo print heads capable of producing an extremely wide color gamut at 1200 DPI, our artwork must be super clean with no imperfections. Sometimes this can be tedious, but well worth the work and still faster than burning screens for screen-printing. Once we feel comfortable with our design we move on to the next step. Sending the file to the printer.

Step 3 - Printing On Garments

After sending the file to the printer all the hard work is done. We then simply dress the platen with your desired shirt, make sure everything is centered and positioned nicely and press the "Go Button." The printer takes over from here, and it is a work horse! Printing a 16 x 21 inch black image in under 60 seconds. Full color in under 2 minutes. Leaving each printer capable of printing almost 250 different high-definition designs with millions of colors in an 8 hour shift. Try that with screen printing!

step 4 - cure the ink

Once printing is complete, we place the garment under high heat and pressure to cure the Eco Friendly Innobella Textile inks. This ensures desired washability for years to come. Direct to garment prints stand up to the test of time and if performed correctly will not peel, flake or fade like other printing methods such as screen-printing or heat transfer vinyl. We use water based, Okeo-Tex Eco-Passport certified, and CPSIA compliant inks. And our innovative replaceable ink pouches use less plastic reducing our ecological footprint.